White semi-rapid set flexible adhesive for natural stone and tiles.

- Ceramic / Porcelain / Mosaics

- Natural stone / Flagstones

- Screeds / Concrete / Timber

- Underfloor heating

- Swimming pools / Wet areas

- Ultimate grab

- Non-slip

- Interior / Exterior

- Average coverage: 6.0sq.m at 3mm thickness for 20kg bag

ROCATEX C2TE S1 Semi-Rapid Flex White is a single part, flexible wall and floor tile adhesive for fixing natural stone and tiles including ceramics, porcelain and mosaics to a variety of substrates. Suitable for interior and exterior use.

SURFACE PREPARATION

All surfaces must be clean, firm, dry, free from all loose matter including dust, dirt, oil, grease, laitance and any other contaminants that may affect adhesion. All substrates should be prepared to provide a rigid and secure base without deflection and suitable to support the intended weight. New timber should be given time to find equilibrium with its surroundings. The following information provides further details for preparing various common substrates. Unless stated otherwise, any reference to the term “diluted” means 1 part primer mixed with 1 part clean water.

Anhydrite Screeds - The substrate must not leach moisture. Anhydrite screeds must not have a moisture content greater than 0.5% or 75% relative humidity (RH). This can easily be tested by taking moisture readings across the whole surface. It is essential that surface laitance is removed in accordance with the screed manufacturer’s recommendations, followed by vacuum cleaning to remove any loose material, then apply 2-4 neat coats of ROCATEX Acrylic Primer or 2 diluted coats of ROCATEX Ultimate Grip Primer.

Concrete Screeds - Prime with 2 diluted coats of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer. Substrate curing before tiling can commence is approximately 6 weeks.

Power Floated Concrete - Once cured, power floated concrete should be mechanically abraded (scabbled or shot blasted) to remove any curing agents and open up the surface, followed by vacuum cleaning to remove any loose material, then apply 2 diluted coats of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer.

Sand & Cement Screeds - Prime with 2 diluted coats of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer. Substrate curing before tiling can commence is approximately 3 weeks.

Gypsum Plaster - The surface should be roughened up using a wire brush or other abrasive tool as this will remove the surface laitance. Ensure surface is clean and free from loose matter and prime with 2 neat coats of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer. Substrate curing before tiling can commence is approximately 4 weeks.

Plaster Boards - Skimming is not required. Prime with 2 diluted coats of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer.

Plywood - Must be a minimum thickness of 15mm, exterior grade, screwed down at 300mm centres and all joints must be supported. Prime the surface with 1 diluted coat of ROCATEX Acrylic Primer or 1 diluted coat of ROCATEX Ultimate Grip Primer.

Tongue & Groove Boards/Floorboards - Must be overboarded with plywood (see above) or use ROCATEX S2 adhesive.

Chipboard - Must be overboarded with plywood (see above) or use ROCATEX S2 adhesive.

Cement Based Tile Backer Boards - Priming is not required if the surface is clean and free from all loose matter. Please note that priming is recommended prior to applying a self levelling compound.

Existing Tiles & Other Non-Porous Substrates - Apply either 1 neat coat of ROCATEX Ultimate Grip Primer and allow to dry or a slurry coat: 1 part cement adhesive powder to 1 part ROCATEX Acrylic Primer, apply a thin coat with a brush and allow to dry.

Flooring Grade Asphalt - Ensure the surface is in good condition and there are no signs of debonding and/or hollowness. Apply 1 neat coat of ROCATEX Ultimate Grip Primer and allow to dry.

Epoxy Damp Proof Membranes - Apply 1 neat coat of ROCATEX Ultimate Grip Primer and allow to dry.

Underfloor Heating - Existing underfloor heating must be switched off at least 3 days prior to tiling to allow the substrate to cool. Once tiling has been completed allow 1 week before turning the heating system back on. Start with a low temperature and gradually increase at 5°C per day.

When tiling on to new electric underfloor heating, we recommend the use of a suitable self levelling compound to encase the heat mat, for example ROCATEX Fibreflow Rapid Flex Leveller. Once tiling has been completed allow 1 week before turning the heating system on. Start with a low temperature and gradually increase at 5°C per day.

MIXING

Mix 20kg of ROCATEX C2TE S1 Semi-Rapid Flex White in a clean mixing vessel with between 4.8 - 5 litres of cold clean tap water until a smooth creamy consistency is achieved using a suitable drill with whisk attachment. Mix at a slow speed for a minimum of 2 minutes to ensure that all ingredients (polymers, retarding agents etc.) are dispersed thoroughly throughout the whole mix.

APPLICATION

The mixed adhesive is applied to the prepared surface and then combed through with a suitably sized notched trowel to create a ribbed adhesive bed. The tiles should be pressed into place with a twisting and sliding action to achieve full adhesive to tile transfer. For tiling to walls in dry internal locations the adhesive contact should be at least 65% of the back of the tile. When tiling to floors and all external situations, or in wet areas such as showers and swimming pools, or when fixing granite and quartz, solid bed fixing should be achieved. To achieve a solid bed requires the tiles to be buttered immediately prior to placing into the ribbed bed so no voids are left beneath the tiles. The size of the notched trowel chosen depends on the size of the tile, the surface being tiled, the profile on the back of the tile and the degree of coverage area required. Expansion joints must be installed in accordance with the relevant Part of BS 5385. Test open time by touching the adhesive bed with a finger; if adhesive transfers to the finger a safe bond is assured, if not, the adhesive must be removed and replaced with fresh material. Never add water or powder to a mix that has begun to set. Do not apply at substrate temperatures below 5°C or in conditions of extreme heat. Exterior installations must be protected from direct sunlight, wind or rain.

GROUTING

Leave for a minimum of 3 hours before grouting and or walking on the tile. This time may be extended on impervious surfaces. If completing a swimming pool do not fill for at least 3 weeks after grouting.

COVERAGE

One 20kg bag will cover approximately 6m2 at 3mm bed thickness.

STORAGE

Store unopened, clear of the ground, in a cool, dry, frost free environment.

TECHNICAL DATA

Conformity: Conforms to the requirements of BS EN 12004 / 12002 C2TE S1

Tensile strength: 24 hrs >1.00N/mm2

Transverse deformation: Classification S1 (deformation greater than or equal to 2.5mm

and less than 5mm)

Application temperature: 5°C to 25°C

Service temperature range: -20°C to +80°C

Bed thickness: 1-20mm

Mixing ratio: 4.8 - 5 litres of clean tap water to 20kg powder

Open time: 45 mins at 20°C

Set time: 5 hrs at 20°C

Ready for grouting: 5 hrs at 20°C

Fully load bearing: 24 hrs at 20°C

Shelf life: 12 months in cool dry area

Sizes: 20kg

Storage: Store unopened clear of the ground in cool dry conditions

Note: All times refer to site conditions of 20°C. These times will be increased at lower temperatures and reduced at elevated temperatures. DO NOT apply if frost is forecast within 24 hours, in wet conditions, in temperatures below 5°C or above 25°C, to areas in direct sunlight or to substrates that are hot.

HEALTH & SAFETY INSTRUCTIONS

Health & safety advice, which must be followed, can be found on the Material Safety Data Sheet. Users are advised to wear face mask, goggles, gloves and overalls when handling, mixing and applying cementitious products. Contains Portland Cement Contains Chromium (VI), which may produce an allergic reaction. Clothing contaminated by wet cement should be removed immediately and washed before re-use. R38 - Irritating to skin. R41 - Risk of serious damage to eyes. S26 - In case of contact with eyes, rinse immediately with water and seek medical advice. S37/39 - Wear suitable gloves and eye/face protection. S2 - Keep out of reach of children. For further information, please request the Material Safety Data Sheet for this product.

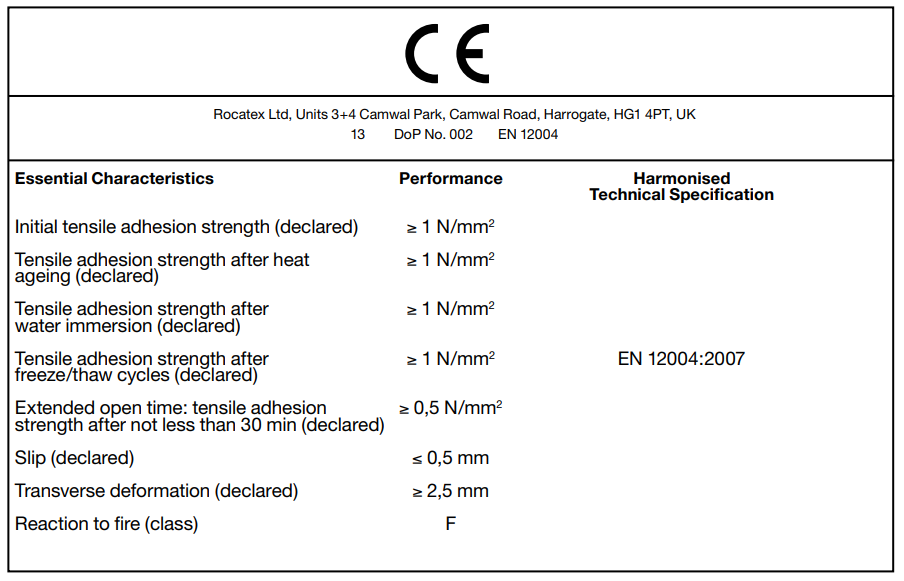

DECLARED PERFORMANCE:

WE ARE A BUSINESS FOR GOOD

As a B1G1 Business For Good, we incorporate purpose and meaning to our business through giving. Together, we are making a great difference in the world.

Through our giving stories, we are able to create micro-giving impacts simply by doing what we do everyday.

For every transaction you make with us, an impact is being created.